IH Cub Cadet Steering Knuckle (MF1025) Development Log (2025-09-21)

Share

Welcome to the latest MF1025 development update from Meisterfabrik, where we document the engineering evolution of our Improved Steering Knuckle Set for early IH Cub Cadet models (70, 71, 72, 73, 100, 102, 104, 105, 106, 107, 122, 123, 124, 125, 126, 127, 147). This project, initiated in 2019, has progressed through detailed analysis and two design iterations, informed by finite element analysis (FEA) and community insights. Let’s explore how we’ve addressed the original steering knuckle’s limitations.

2019 OEM Technical Assessment

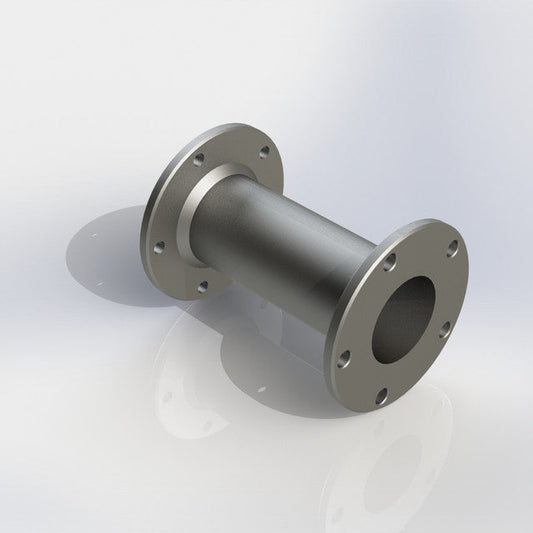

The IH original equipment includes a pair of left- and right-hand steering knuckle assemblies, each featuring an "L" shape. The lower end of each knuckle serves as a spindle, mounting the front wheel on bearings, while the upper section forms a rotational hinge-style joint with the cast iron axle. This design utilizes the tractor's weight as the primary retention mechanism for the knuckle assemblies, supplemented by secondary retention components: a pin and drag arm on the left, and a bolt and washer on the right. The left-hand knuckle acts as the master assembly, channeling force from the steering wheel through the drag link and drag arm to turn itself, while also transmitting this motion to the right-hand knuckle via a tie rod.

Failure Modes

Our 2019 evaluation of the OEM IH Cub Cadet steering knuckle design, enhanced by finite element analysis (FEA) results including factor of safety (FOS) plots, subjected the assembly to maximum estimated operating loads. The FEA applied a drag link load of 375 lbf (~1668 N) at the drag arm and a wheel bearing load of 215 lbf (~956 N) at the spindle, based on a tractor weight of 655 lbs with a 40/60 front/rear weight distribution, further adjusted to include an additional 168 lbs from IH add-on front weights. The FOS plots, derived from the FEA model "20204020005" (study "Applied Steering Loads (Pin Type Variation)"), reveal critical design deficiencies: safety factors fall below acceptable levels around the pin joint (highlighted in red zones), confirming its vulnerability to shearing due to fatigue. Additionally, the bent spindle section exhibits low FOS values, indicating a propensity for shear failure under dynamic loads, with a maximum displacement of 0.0661 inches (~1.68 mm) concentrated in these areas. These findings, cross-verified by the FEA’s stress distribution and field observations, establish that shearing at the bend section and around the pin diameter are inherent design flaws, necessitating a robust redesign to enhance durability.

2019 Initial Design

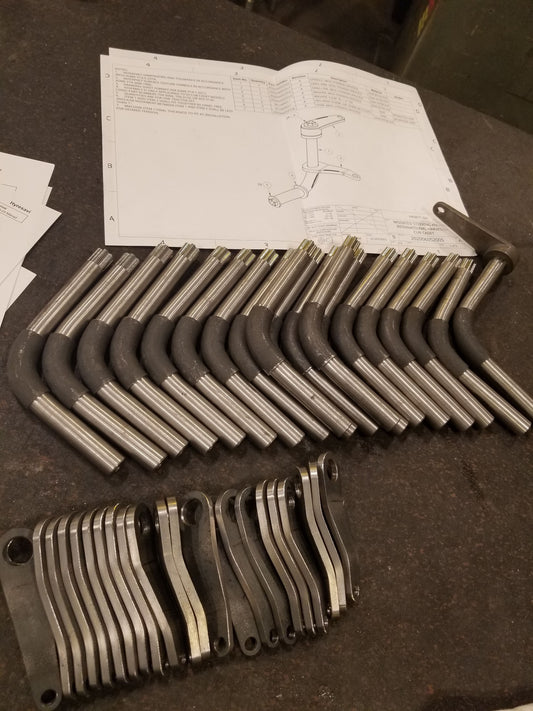

Our 2019 limited-release first-generation (18 LH Knuckle Assemblies) upgrade introduced:

- A36 steel (yield ~250 MPa) to increase strength and durability.

- A larger diameter cross-section through the bent segment.

- Custom Torx connection to mitigate pin fatigue.

- A shim to reduce steering load stress.

While FEA confirmed A36 handled stresses (~2.51 MPa vs. 250 MPa), the bent spindle’s deformation and the overlooked 10-degree drag arm advancement prompted further refinement.

What Did We Get Wrong?

Reverse engineering proved to be a formidable challenge—slow clap for China. Our initial design erroneously assumed the spindle axis and drag arm mid-plane were coincident, a miscalculation later identified as approximately 10 degrees advanced. Overwhelming feedback from users highlighted this discrepancy, prompting us to introduce a shortened drag link as a temporary "band-aid" solution.

2025 Current Design Enhancements (MF1025)

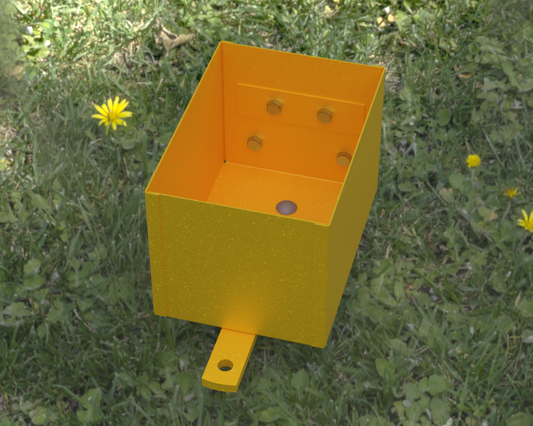

Our second-generation Improved Steering Knuckle Set, available soon (MF1025), incorporates:

- A two-part welded spindle assembly, eliminating the fatigue-prone bend and distributing loads more evenly.

- A T80 Torx drive for the drag arm connection, improving torque transfer under ~1668 N forces.

- S355J2 steel (yield ~355 MPa) for superior strength, with a black oxide coating for corrosion resistance.

- Corrected 10-degree drag arm geometry and RH/LH options, ensuring compatibility with models 70–147.

Production Progress

We are deep into full‑scale manufacturing of the MF1025 steering‑knuckle assemblies for field testing. With a brand‑new workshop and a freshly engineered design, we’re tackling a host of small‑detail challenges step by step. After deliberately dismantling one complete left‑hand (LH) assembly to expose hidden issues, we incorporated the lessons learned into our welding process. As a result, the first full set of steering‑knuckle assemblies has now been welded and passed all post‑weld inspections.

The next milestone is completing the second full set of welds. Once that set is finished, we will move straight into the black‑oxide treatment stage, applying the protective coating and then proceeding with final assembly and functional testing. This systematic approach lets us iterate quickly, capture every nuance, and ensure the final product meets our durability and performance targets.

Community and Future Directions

Feedback from restorers, including the need for RH knuckles, shaped this update. Future work may explore bushing enhancements or broader steering system modifications to improve longivity and precision steering response.

The Improved Steering Knuckle Set is ready to enhance your Cub Cadet’s performance. Stay tuned for more SparkVerk updates.